The Team

Awards

Michigan Athletics Communications Design

I am currently interning with the University of Michigan Athletic Department for my second year as a Graphic Designer. My responsibilities include using the Adobe Creative Suite to produce a high volume of print and digital assets to support the promotion of the University’s athletic programs, its teams and events. Examples of projects I have worked on include creating logos, posters, flyers, billboards, event programs, apparel, newsletters, and info-graphics for Michigan Athletic programs. Several of the sports I have worked on the following U-M athletic teams: Basketball, Football, Ice Hockey, Gymnastics, Tennis, Soccer, Baseball, Softball, Wrestling, Swimming & Diving, Golf and Lacrosse.

Big House 5K 2019 Branding

Final Project - CNC Milling

Brief - CNC milling is a prominent process within the digital fabrication world. Using all skills gained from the first part of the semester students will apply this process to a final project relevant to the course. Each student will develop a workflow that uses not only this technology but includes at least one other digital fabrication process.

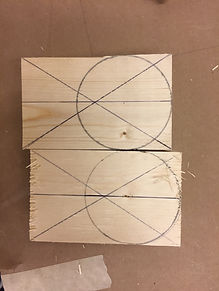

Wood Joining Exploration

An improvement on the notch joint, this method securely joins two separate pieces of wood together. Due to the opposing angles the wood does not slide back and forth or sideways.

Articulated Wood Joints

Angled Joints

Precision milling allowed for the cutting of exact angles. Exploring these different angles reveals the possible use of these joints. Two angles, each perpendicular to one of the surfaces of the shape can allow for many different attachments methods that promise varying degrees of articulation and use.

+1 Angle

Triangle + 3 joining angles

To increase the intellectual fidelity of my digitally fabricated joint, I decided to create a shape with 3 non 90 degree angles. In addition to this, I also sought to create 3 different angles within the shape itself. This way by utilizing all the different angles, the joint will be able to take on many different types on combinations.

Rounded Triangles

Vinyl Stickers

The addition of vinyl on the outer faces of the rounded triangles will allow the user to experiment how the rounded triangles are meant to be joined. There are four colors of vinyl on the faces of the shape to highlight show that there is more than just one combination.

A few (not all) joining combinations

Final Prototypes

Built-in Technology

Taking feedback I received from my peers, I decided to make a small change to the original triangle. Using the cnc milll, I was able to prototype a triangle with small indentations in the face of the shape. This way, the shape has two angles built into it, allowing for the joining at different angles

Intuitive Shape Design

The joining shape was also redesigned to better fit with the new base. This was done in order to allow for the new shape to join at different angles. By designing a small extrusion onto a rectangle, the shape can not only fit into the 90 degreed indentation but also fit into the 60 degree angle on the face of the base.

Shape Joinery

With the redesigned base and new shape, my digitally fabricate base and hand made attaching shapes can be joined at a number of different angels, expanding the utility and application of the joint.

A few (not all) joining combinations